Eliminating Harvest Downtime: Why Custom-Machined Replacement Parts are Faster (and better) than OEM Shipping

January 11, 2026 3:46 pm Leave your thoughtsWhen the harvest season arrives, time becomes a critical factor. Farmers rely on their agricultural machinery to operate flawlessly, as even a brief interruption can result in significant crop loss and revenue setbacks. A common source of disruption comes from mechanical failures or worn-out components that require immediate replacement. Traditionally, many turn to Original Equipment Manufacturer (OEM) parts for their repairs. However, a growing number of agricultural professionals are finding that custom-machined replacement parts provide a faster and more effective solution.

In the high-stakes environment of agricultural machinery maintenance, every moment counts. Waiting for OEM parts to arrive, especially during peak season, can lead to avoidable downtime and stress. This article explores why custom-machined parts not only offer a quicker response to urgent repairs but can also outperform OEM parts in several key areas.

The Time Cost of OEM Shipping During Harvest

One of the biggest disadvantages of relying on OEM parts is shipping time. Manufacturers often have centralized distribution hubs that can be hundreds or even thousands of miles away from the farm. During harvest season, when demand for arm equipment repair parts is at its peak, shipping times can increase dramatically due to backorders, logistic bottlenecks, or supply chain disruptions.

Even expedited shipping rarely guarantees overnight solutions, especially for rural locations that many farms occupy. By the time the part arrives, the downtime may have already impacted crop yields. What’s more, OEM parts are frequently tailored for specific models and years. If a machine is older or has been modified, compatibility becomes another delay-inducing hurdle.

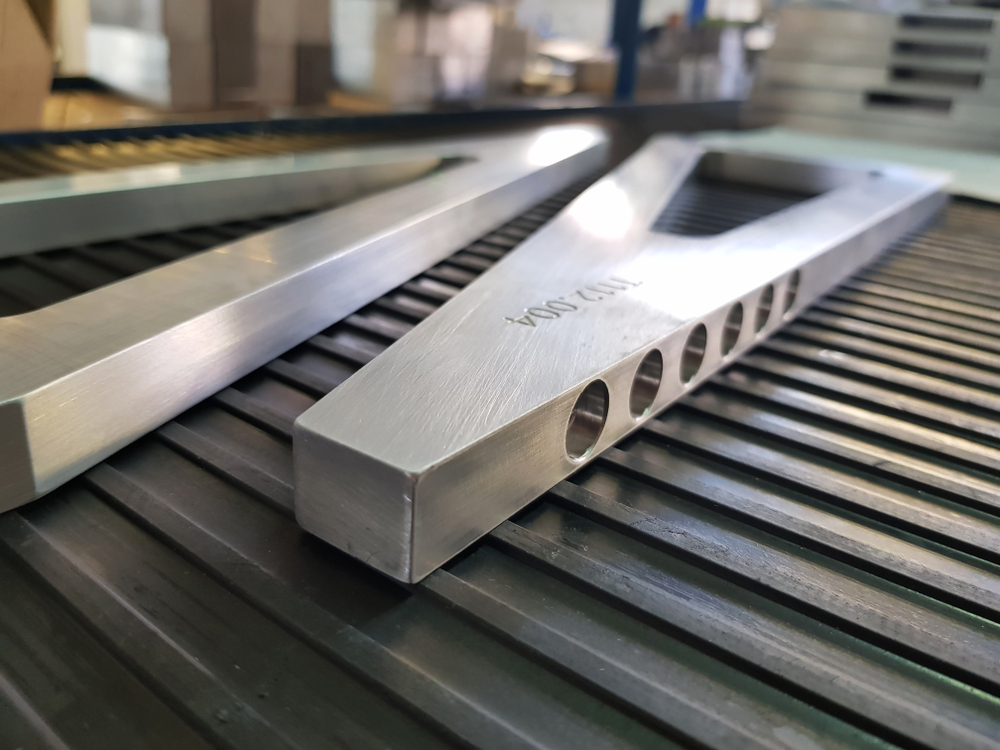

In contrast, local machine shops or specialized fabricators can produce custom parts in a fraction of the time. Once the broken or worn part is identified, it can be brought to a shop that analyzes its structure and immediately begins crafting a replacement. Many of these shops are equipped with CNC machines and skilled technicians who understand agricultural machinery maintenance intimately. The turnaround time can be reduced from days or weeks to mere hours.

Superior Fit for Modified or Legacy Equipment

Agricultural machinery often remains in service well beyond its expected lifespan. Modifications, retrofits, and custom adaptations are common to extend the usefulness of older equipment or to enhance performance under specific conditions. OEM parts are typically designed with standard specifications that may no longer align with a machine’s current configuration.

This is where custom-machined replacement parts provide a major advantage. A skilled machinist can create components that match the exact requirements of modified or legacy machinery. They can account for wear patterns, unique geometries, and previous alterations, producing a part that integrates seamlessly with the current system.

Moreover, farmers who have adopted innovative solutions or built customized implements often find OEM parts to be an imperfect fit. The flexibility of custom machining ensures that the new part doesn’t just replace the old one, but improves upon it. This precise customization is rarely possible with off-the-shelf parts.

Material and Performance Advantages

While OEM parts are made to meet the manufacturer’s original specifications, that doesn’t always mean they are the most durable or efficient option. In some cases, OEMs select materials that balance cost with functionality, which can result in parts that wear out faster under heavy use or harsh environmental conditions.

Custom-machined parts can be built with superior materials selected for the specific application. Whether it’s higher-grade steel, corrosion-resistant alloys, or advanced composites, machinists have access to a broader material palette than most OEM supply chains. This allows for the creation of parts that withstand more stress, resist environmental wear, and deliver longer operational lifespans.

In addition, the design of custom parts can be optimized for performance. Features such as reinforced edges, improved lubrication channels, or modified shapes to reduce friction can be integrated into the design. These enhancements not only restore functionality but can elevate machine performance beyond what the original part offered.

Local Expertise and Collaborative Problem Solving

Farmers working with local machine shops gain access to more than just replacement parts. They enter a partnership with technicians who often have deep experience in arm equipment repair parts and agricultural machinery maintenance. These experts can help diagnose complex mechanical issues, suggest improvements, and even anticipate potential failures.

This collaborative problem-solving approach is far removed from the transactional nature of ordering OEM parts online or through dealers. Machine shops are often willing to work side-by-side with farmers to understand the exact function of a part, analyze failures, and engineer solutions tailored to the equipment and operating conditions.

In rural areas, these relationships can become invaluable. Having a reliable machine shop within driving distance means that emergencies are handled swiftly and creatively. In many cases, machinists can make on-the-spot recommendations that improve machinery reliability for future harvests, reducing the chance of repeat failures.

Cost-Effectiveness Beyond the Price Tag

It’s easy to assume that OEM parts are more affordable because they are mass-produced. However, this perception doesn’t always hold true when factoring in total cost of ownership. OEM parts can include hidden costs such as shipping, import taxes, dealer markups, and the potential need for additional components to ensure compatibility.

Custom-machined parts may have a higher upfront cost, but they frequently deliver better value over time. Their improved durability and performance can reduce the frequency of replacements and minimize additional damage that might occur during downtime. When machinery is offline during critical periods like harvesting, the cost of waiting often far exceeds any savings gained from ordering OEM components.

Furthermore, having the ability to repair or replace parts locally creates a sense of independence and resilience. Farmers are no longer at the mercy of distant suppliers or unpredictable shipping timelines. They gain control over their repair process, enabling quicker decisions and immediate action.

Conclusion

Harvest downtime is a costly and stressful reality that farmers strive to avoid. While OEM parts have their place in agricultural machinery maintenance, they often fall short when timing, customization, or performance are critical. Custom-machined replacement parts offer a compelling alternative that minimizes wait time, improves fit and function, and can even outlast the original components.

The ability to work directly with skilled machinists, choose superior materials, and receive personalized solutions gives farmers a significant edge during harvest. In a field where minutes can make a difference, the speed and reliability of custom parts help ensure that the season’s efforts result in a full and successful yield.

Investing in local machining resources not only supports the broader agricultural community but also reinforces the operational stability of farms. For those managing arm equipment repair parts and looking to optimize agricultural machinery maintenance, turning to custom machining may be the smartest choice in the long run.

Need Steel Fabricators in Hermiston, OR?

NW Metal Fabricators, Inc. is a family-owned business that has been servicing customers in Hermiston, Oregon since 1986. We have more than 100 years of experience in the food-processing industry and specialize in the custom production of storage bins, conveyors, catwalks, handrails, gates, storage tanks, water heater tanks, sanitary piping, steam piping, and trailer truck hitches. NW Metal Fabricators, Inc. is an accredited member of the local Chamber of Commerce. We are a dedicated business where quality always comes first. Our customers know that they can count on us to make sure that their products are hand-crafted to meet their specifications. Contact us today to learn more about what we can do for you!

Categorised in: Metal Fabrication Products

This post was written by admin