Industrial Machining Solutions for Agriculture and Manufacturing

November 7, 2025 5:50 pm Leave your thoughtsToday, agriculture and manufacturing are two of the most demanding and technologically advanced industries. Their progress depends heavily on precision, efficiency, and the ability to adapt quickly to changing market demands and environmental conditions. One of the most transformative forces behind this progress is industrial machining. With its ability to fabricate, shape, and finish parts to exact specifications, machining has become essential to driving innovation and productivity. Whether it’s building high-performance parts for tractors or developing assembly line components for factories, the role of industrial machining services is pivotal.

This blog explores the ways in which industrial machining solutions are revolutionizing agriculture and manufacturing. It also delves into the specialized role of CNC machining for agricultural applications, where accuracy and customization are key. As global demand for smarter, more efficient machinery grows, so does the importance of precision machining in supporting that evolution.

The Role of Industrial Machining in Modern Agriculture

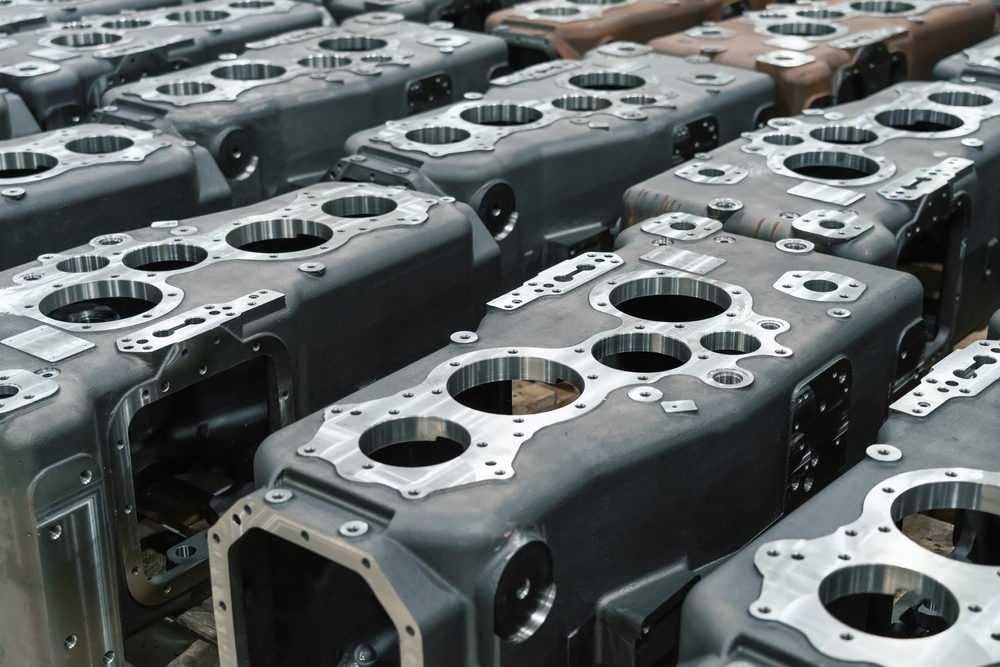

Modern agriculture has moved far beyond the era of manual labor and rudimentary tools. Today, it operates on the backbone of advanced machinery—tractors, harvesters, irrigation systems, and precision seeders—all of which depend on reliable components that must withstand the test of time and extreme working conditions. Here, industrial machining services become essential by manufacturing durable and accurate parts that support these machines.

CNC machining for agricultural equipment is especially valuable because of its ability to produce highly specialized components quickly and efficiently. Farmers now rely on GPS-guided systems, automated plows, and smart irrigation units that require exact specifications to function properly. A minor defect in a component can compromise productivity and lead to costly delays during crucial planting or harvesting seasons.

Furthermore, as agricultural machinery becomes more digitized and autonomous, the demand for tight tolerances and precise geometries continues to rise. CNC machining enables manufacturers to meet these rigorous requirements by using computer-controlled processes to fabricate parts with exceptional repeatability. From custom nozzles used in spraying systems to engine components designed for fuel efficiency, CNC machining for agricultural machinery plays a crucial role in optimizing farm performance.

Advancing Manufacturing Efficiency with Machining

Manufacturing, like agriculture, is undergoing rapid transformation. The rise of automation, robotics, and data analytics has elevated expectations for precision and speed. At the center of these innovations are industrial machining services that provide critical support in designing and producing machine parts, tools, and fixtures used throughout production lines.

Manufacturing companies often operate under tight schedules and budgets. Any failure in a production component can bring entire operations to a halt. To mitigate such risks, manufacturers rely on machining partners that deliver quality components with quick turnaround times. CNC machining, in particular, allows for scalable production, enabling manufacturers to test prototypes, refine designs, and move quickly into full-scale production with confidence in the quality of each part.

Industrial machining services also support sustainability efforts within the manufacturing sector. By fabricating precision parts that fit together perfectly, companies can reduce material waste, lower energy consumption, and extend the lifespan of machinery. This not only enhances environmental performance but also contributes to long-term cost savings.

In industries such as automotive, aerospace, and electronics, tolerances can be as fine as a thousandth of an inch. Meeting these requirements consistently would be impossible without advanced machining capabilities. As a result, machining providers must continue investing in high-end equipment, skilled labor, and quality control systems to support the ever-evolving needs of the manufacturing industry.

Customization and Innovation Through CNC Machining

One of the most powerful features of CNC machining is its ability to accommodate custom designs and unique geometries. This is especially valuable for both agriculture and manufacturing, where one-size-fits-all solutions often fall short. In agriculture, for example, soil composition, climate, and crop type vary from region to region. Farmers may require specific attachments or configurations that aren’t available in off-the-shelf products. CNC machining for agricultural tools allows for custom-built parts tailored to these localized needs.

In manufacturing, the demand for innovation often means developing new products with never-before-seen features or engineering modifications. CNC machining excels at creating prototypes with quick iteration cycles, allowing engineers to test and refine their ideas rapidly. These custom components can then be scaled into mass production without sacrificing quality.

The technology behind CNC machining is also advancing rapidly. Modern CNC machines are capable of multi-axis operations, which means they can handle complex designs in a single setup. This reduces production time and increases accuracy. Integration with CAD/CAM software allows for seamless transition from digital design to physical part, eliminating manual errors and enhancing efficiency.

CNC machining’s precision and adaptability also make it ideal for retrofitting or upgrading existing machinery. Instead of replacing entire systems, manufacturers and farmers can use custom-machined components to enhance performance or extend the life of their equipment. This makes CNC machining not only a tool for innovation but also a cost-effective strategy for sustainability.

Materials and Techniques That Drive Performance

Industrial machining is not just about cutting metal. It involves a broad spectrum of materials and techniques designed to meet the diverse needs of agriculture and manufacturing. From aluminum and stainless steel to polymers and composites, machining services must be able to work with a wide variety of substrates. Each material presents its own challenges in terms of hardness, thermal conductivity, and machinability.

In agriculture, components often require resistance to corrosion, moisture, and heavy wear. This means machining providers must choose materials and coatings that can survive in outdoor and abrasive environments. For example, tillage tools and plow blades may be coated with wear-resistant finishes to enhance durability.

In manufacturing, thermal and structural stability may take precedence. Parts used in high-speed production lines must resist heat deformation and maintain dimensional accuracy under constant use. Precision machining ensures that these parts meet strict performance criteria while remaining consistent from batch to batch.

Advanced techniques such as 5-axis machining, electrical discharge machining (EDM), and laser cutting have further expanded the possibilities for creating intricate, high-performance parts. These methods allow for complex shapes, internal channels, and fine details that were once thought impossible. For both agriculture and manufacturing, the availability of these techniques means greater functionality, reliability, and innovation in end-use products.

Partnering with the Right Machining Service Provider

Choosing the right provider of industrial machining services can significantly impact the success of projects in agriculture and manufacturing. A reliable partner brings more than just machines—they bring experience, engineering insight, and a commitment to quality. This relationship should be built on clear communication, shared goals, and a deep understanding of the industry-specific challenges.

For agricultural applications, this means finding a machining partner who understands the seasonal nature of farming and the urgency of equipment availability. Quick turnaround, part availability, and customization options are essential features of a capable service provider. CNC machining for agricultural tools and systems must meet both functional and time-sensitive demands.

In manufacturing, the right partner can be the difference between a successful product launch and a costly delay. They must offer design support, prototyping capabilities, and scalable production. Experience with regulatory standards and quality certifications is also important, especially in industries with high safety or performance requirements.

Trust and transparency are key to long-term partnerships. Machining providers should be willing to share insights, suggest improvements, and collaborate closely with clients to ensure optimal outcomes. As technology continues to evolve, partnerships that embrace innovation, adaptability, and continuous improvement will thrive in this space.

Conclusion

Industrial machining solutions are the invisible engine behind the visible success of agriculture and manufacturing industries. From rugged tractor components to intricate production tools, these services ensure that machines perform reliably, efficiently, and precisely. With the integration of CNC machining for agricultural equipment and manufacturing systems, companies are better equipped to meet the demands of today’s market.

The value of industrial machining services extends far beyond fabrication. It empowers innovation, enables customization, and drives sustainability. As these industries continue to grow and adapt to new technologies and global challenges, machining will remain a cornerstone of their progress. By investing in high-quality machining partnerships and embracing advanced capabilities, businesses in agriculture and manufacturing can secure a competitive edge and pave the way for future success.

Need Steel Fabricators in Hermiston, OR?

NW Metal Fabricators, Inc. is a family-owned business that has been servicing customers in Hermiston, Oregon since 1986. We have more than 100 years of experience in the food-processing industry and specialize in the custom production of storage bins, conveyors, catwalks, handrails, gates, storage tanks, water heater tanks, sanitary piping, steam piping, and trailer truck hitches. NW Metal Fabricators, Inc. is an accredited member of the local Chamber of Commerce. We are a dedicated business where quality always comes first. Our customers know that they can count on us to make sure that their products are hand-crafted to meet their specifications. Contact us today to learn more about what we can do for you!

Categorised in: Machining

This post was written by admin