Top Industries That Benefit from Custom Metal Fabrication in the Pacific Northwest

October 10, 2025 1:47 pm Leave your thoughtsThe Pacific Northwest, encompassing states like Oregon and Washington, has long been recognized for its strong industrial backbone and innovative manufacturing spirit. From agriculture and renewable energy to construction and maritime operations, the region thrives on industries that require durable, reliable, and precisely engineered metal components. Custom metal fabrication plays a critical role in supporting this ecosystem, enabling businesses to achieve efficiency, safety, and longevity in their operations.

In this article, we’ll explore the top industries that rely on custom metal fabrication in the Pacific Northwest, examining how fabrication services for agriculture, energy, construction, transportation, and manufacturing continue to shape the regional economy.

Agriculture: Strength and Precision in Equipment Design

Agriculture has been one of the cornerstones of the Pacific Northwest’s economy for decades. In states like Oregon and Washington, farming operations rely heavily on robust equipment and infrastructure that can withstand varied weather conditions and challenging terrain. Custom metal fabrication provides agricultural businesses with tailored solutions designed for maximum durability and efficiency.

Fabrication services for agriculture encompass a wide range of applications, including the production of irrigation systems, grain storage facilities, animal enclosures, conveyors, and harvesting equipment. Farmers and agricultural engineers often prefer custom metal components because they can be engineered to precise specifications that off-the-shelf parts simply cannot meet.

Moreover, local fabricators in Oregon and Washington understand the specific agricultural needs of the region, from the fruit orchards of the Willamette Valley to the vast wheat farms in Eastern Washington. By using locally sourced materials and advanced industrial metal fabrication techniques, these specialists deliver solutions that improve operational performance while supporting sustainability goals.

Energy Sector: Powering the Pacific Northwest with Fabrication Expertise

The Pacific Northwest has become a national leader in clean and renewable energy initiatives. From hydroelectric power to wind and solar projects, energy infrastructure depends on high-quality metal components for safety and performance. Fabrication services for energy are essential to ensure that turbines, pipelines, and support structures can operate efficiently under extreme conditions.

Custom metal fabrication provides the flexibility and precision required to manufacture complex components for both traditional and renewable energy facilities. For example, hydroelectric plants rely on fabricated steel penstocks and gates, while wind farms require towers and frames built to exact engineering standards. Solar installations also benefit from lightweight but strong mounting systems made through precision fabrication.

The local expertise available in Oregon and Washington gives energy companies a unique advantage. Regional fabricators are familiar with the engineering standards and environmental requirements specific to the Pacific Northwest. As a result, they can deliver components that meet rigorous safety and regulatory standards while minimizing transportation costs and environmental impact.

Industrial metal fabrication also plays a vital role in the maintenance of existing infrastructure. Aging energy systems require continuous upgrades, and custom fabrication allows engineers to retrofit parts without disrupting operations. This adaptability ensures long-term reliability, making custom fabrication an invaluable asset to the Pacific Northwest’s growing energy industry.

Construction and Architecture: Building the Region’s Future

From commercial buildings in downtown Seattle to infrastructure projects across Oregon, the construction industry is one of the largest beneficiaries of custom metal fabrication. The versatility of fabricated metal allows architects and builders to bring creative and functional designs to life while maintaining structural integrity.

Steel and aluminum are the materials of choice for modern construction due to their strength, durability, and sustainability. Through advanced fabrication processes, metal can be shaped into beams, columns, staircases, railings, and architectural facades. Custom fabrication services allow for precision cutting, welding, and finishing, ensuring every component aligns with the project’s specifications and design intent.

In urban development, fabricated metal structures offer a sleek and modern aesthetic while meeting stringent safety and environmental standards. In rural and industrial projects, custom metal components provide unmatched durability, standing up to harsh conditions and heavy use.

Local fabricators in the Pacific Northwest bring additional value by offering short lead times, responsive communication, and regional expertise. Oregon and Washington construction firms often prefer working with nearby metal fabrication shops to streamline logistics, reduce costs, and ensure quality control throughout every phase of a project.

Transportation and Marine Industries: Keeping the Pacific Northwest Moving

The Pacific Northwest’s geography makes transportation and maritime activity critical to its economy. Ports, railways, and logistics companies depend on precision-engineered metal components for safety, efficiency, and performance. Custom metal fabrication supports this industry by producing everything from ship components and cargo containers to railings, ladders, and heavy-duty storage racks.

In Oregon and Washington, the marine industry has a long history of innovation. Shipbuilders and maintenance yards rely on local fabricators to produce corrosion-resistant components that can withstand constant exposure to saltwater and heavy loads. Stainless steel and aluminum are commonly used materials due to their strength and resistance to rust.

Transportation companies also benefit from industrial metal fabrication when constructing or maintaining fleets of trucks, trailers, and railcars. Custom frames, brackets, and platforms ensure vehicles can handle heavy cargo while adhering to safety regulations. The flexibility of custom fabrication allows engineers to modify existing designs, improving efficiency without requiring full equipment replacement.

By partnering with experienced Pacific Northwest fabricators, transportation and marine businesses gain access to local expertise, quick turnaround times, and durable products built for the region’s demanding conditions.

Manufacturing and Industrial Applications: Innovation through Metal

The Pacific Northwest’s manufacturing sector is a diverse ecosystem that includes aerospace, electronics, machinery, and food processing. Each of these industries relies on custom metal fabrication to maintain precision, quality, and consistency in production processes. Industrial metal fabrication services allow manufacturers to design and implement specialized equipment tailored to their specific operations.

In aerospace and high-tech industries, for example, fabrication must meet strict tolerances to ensure product reliability. Oregon and Washington are home to numerous companies that supply parts and machinery to Boeing, Intel, and other major manufacturers. Custom fabrication enables these businesses to meet exacting specifications and maintain global competitiveness.

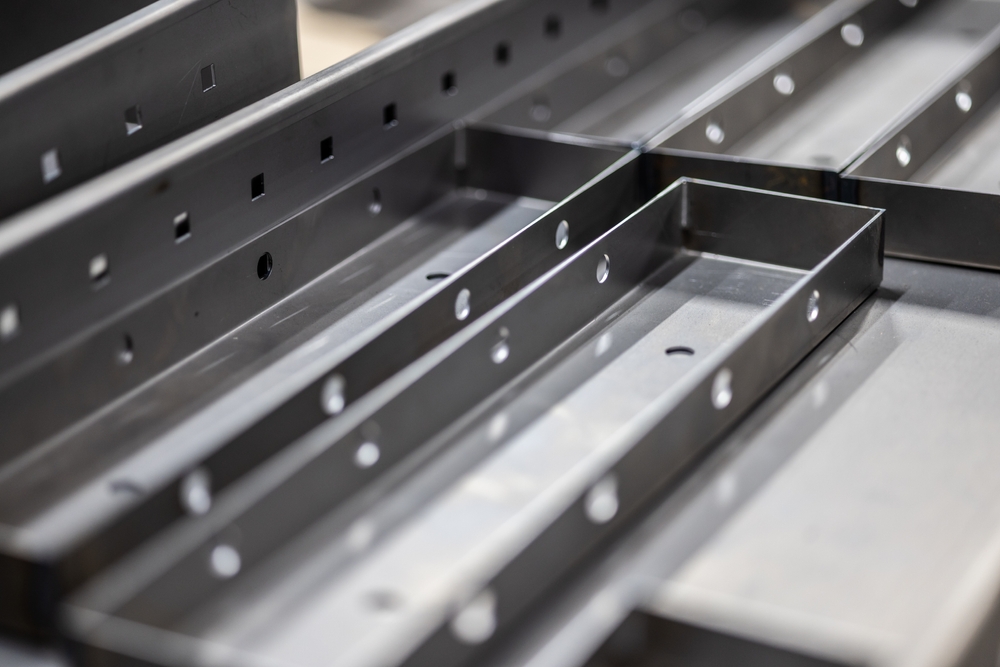

Food and beverage processors also depend on stainless steel fabrication for sanitary equipment such as conveyors, mixers, and tanks. The ability to design and fabricate corrosion-resistant systems ensures compliance with health standards and improves production efficiency.

What sets Pacific Northwest fabricators apart is their integration of advanced technology and craftsmanship. Many shops utilize computer-aided design (CAD), laser cutting, and robotic welding to achieve unparalleled accuracy and repeatability. These innovations not only enhance productivity but also reduce waste and support sustainable manufacturing practices.

Conclusion

Custom metal fabrication is the backbone of many of the Pacific Northwest’s most vital industries. From the farms of Oregon to the energy facilities of Washington, the versatility and precision of metal fabrication enable businesses to meet their goals with efficiency and reliability. Whether it’s fabrication services for agriculture and energy or large-scale construction and manufacturing projects, the region’s fabricators play a pivotal role in driving innovation and economic growth.

As the Pacific Northwest continues to evolve, so too will the demand for advanced fabrication solutions. Local expertise, sustainable practices, and cutting-edge technology ensure that custom metal fabrication remains an essential part of the region’s future, supporting industries that power, build, and move the world forward.

Need Steel Fabricators in Hermiston, OR?

NW Metal Fabricators, Inc. is a family-owned business that has been servicing customers in Hermiston, Oregon since 1986. We have more than 100 years of experience in the food-processing industry and specialize in the custom production of storage bins, conveyors, catwalks, handrails, gates, storage tanks, water heater tanks, sanitary piping, steam piping, and trailer truck hitches. NW Metal Fabricators, Inc. is an accredited member of the local Chamber of Commerce. We are a dedicated business where quality always comes first. Our customers know that they can count on us to make sure that their products are hand-crafted to meet their specifications. Contact us today to learn more about what we can do for you!

Categorised in: Metal Fabrication

This post was written by admin