How Precision Machining Improves Final Product Quality

August 9, 2025 3:55 pm Leave your thoughtsPrecision machining is an essential component of modern manufacturing, enabling the creation of parts and components that adhere to exact specifications. From aerospace to medical devices, the ability to craft intricate parts with remarkable consistency and accuracy dramatically influences the quality of the final product. While traditional machining techniques have served industries for decades, high tolerance machining is now a cornerstone of quality assurance and performance excellence. In this article, we explore how precision machining enhances the final product quality across various sectors and why manufacturers increasingly invest in this advanced capability.

Understanding Precision Machining and Its Capabilities

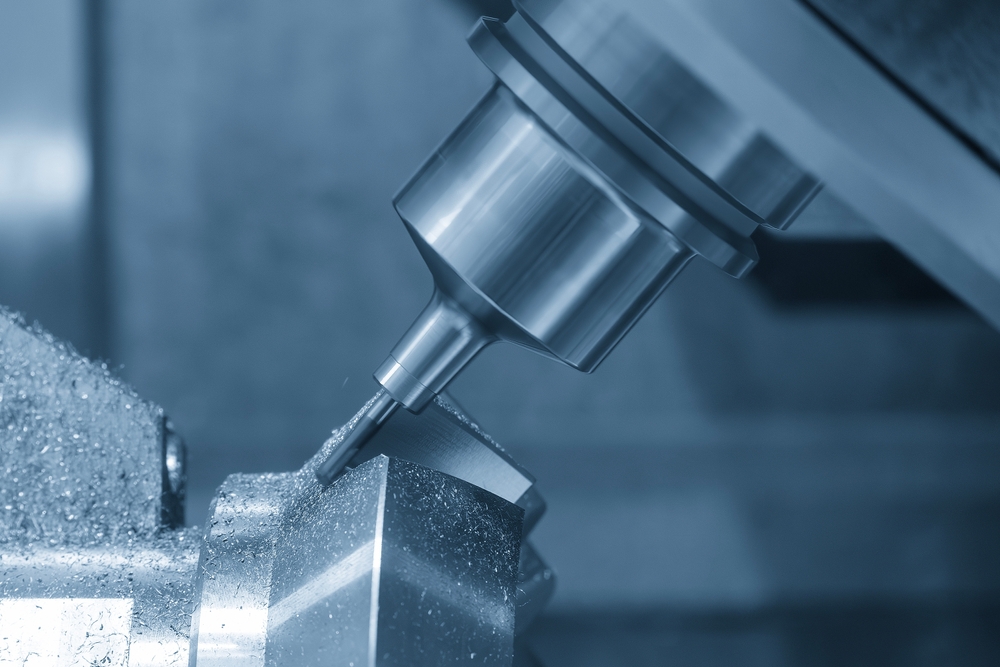

Precision machining refers to the process of removing material from a workpiece to create components that meet very specific design tolerances—often within thousandths of an inch. The term encompasses a variety of advanced techniques and tools such as CNC (Computer Numerical Control) milling, turning, grinding, and electrical discharge machining (EDM). These methods are capable of producing parts that conform to exact blueprints with minimal variability.

The strength of precision machining lies in its capacity to achieve high repeatability and detail even in complex geometries. This is especially critical for industries like aerospace, automotive, electronics, and healthcare, where the performance and safety of end products rely heavily on the precision of each part. High tolerance machining allows manufacturers to meet stringent design criteria that would be impossible with manual or less sophisticated machining processes.

The benefits of precision machining extend beyond mere accuracy. It reduces material waste, lowers operational costs in the long run, and significantly improves time-to-market due to minimized rework and tighter production controls. With digital integration and automation, precision machining now plays a vital role in smart manufacturing environments, promoting consistent output and streamlined workflows.

Enhancing Component Fit and Functionality

One of the most immediate ways that precision machining improves final product quality is through superior component fit and functionality. In assembly-based products, even a minor dimensional deviation in a single component can compromise the integrity and performance of the entire system. High tolerance machining ensures that each part is manufactured within the tightest specifications, allowing for seamless assembly and reliable operation.

In mechanical assemblies, precise fits reduce friction, wear, and mechanical play, all of which can contribute to long-term degradation. In applications such as engines or gear systems, misalignment or excess clearance can lead to increased vibration, noise, and premature failure. Precision-machined components eliminate these issues, enhancing both the short-term performance and longevity of the product.

Furthermore, products that depend on fluid or gas transfer—like hydraulic systems or medical pumps—require parts with extremely accurate dimensions to ensure tight seals and regulated flow. Precision machining enables manufacturers to create those perfect fits, which in turn improves efficiency and prevents leakage, contamination, or system failure.

Improving Product Reliability and Safety

Reliability and safety are paramount in critical industries such as aerospace, defense, and medical technology. In these sectors, any failure—no matter how small—can lead to catastrophic consequences. Precision machining enhances product quality by minimizing variability and ensuring consistent performance, which is critical for meeting stringent industry regulations and standards.

For example, in the aerospace sector, turbine blades, landing gear components, and structural supports must not only perform under extreme conditions but also undergo rigorous certification. With the benefits of precision machining, manufacturers can produce these parts with microscopic accuracy, ensuring uniformity and structural integrity. Likewise, in the medical field, implants and surgical instruments must adhere to tight tolerances to ensure patient safety and effective treatment. A deviation of even a few microns could result in device malfunction or compatibility issues within the human body.

High tolerance machining also plays a pivotal role in non-destructive testing (NDT) and quality assurance workflows. Since components are produced with such consistency, deviations from standard measurements are easier to detect, allowing for more efficient and accurate inspection processes. This proactive approach minimizes the risk of defective products reaching end users and supports a culture of quality from the ground up.

Supporting Innovation and Complex Design Implementation

As product designs become increasingly sophisticated, the need for advanced manufacturing capabilities grows. Precision machining enables designers and engineers to push the boundaries of innovation without being constrained by manufacturing limitations. Intricate geometries, micro-scale features, and custom configurations are all achievable thanks to the benefits of precision machining.

Advanced materials—such as titanium, Inconel, and specialized polymers—often require machining under strict process controls to prevent warping, cracking, or loss of material integrity. Precision machining technologies are uniquely suited to handle such requirements. This capability allows manufacturers to adopt cutting-edge materials that enhance product performance, whether through weight reduction, thermal resistance, or chemical durability.

Moreover, in prototyping and R&D, precision machining accelerates product development cycles. Engineers can iterate quickly, producing multiple design variations with consistent quality and precision. This not only facilitates experimentation and refinement but also shortens the path from concept to market-ready product.

As industries move toward mass customization, the role of high tolerance machining becomes even more vital. It allows manufacturers to efficiently produce small batches or one-off components that meet the same rigorous standards as mass-produced items. This flexibility enables companies to cater to niche markets or rapidly changing customer demands without compromising on quality.

Driving Long-Term Cost Efficiency and Sustainability

While the upfront investment in precision machining equipment and skilled labor may be high, the long-term financial and environmental returns are substantial. High tolerance machining reduces material waste by optimizing cutting paths and eliminating the need for excessive finishing or rework. This lean manufacturing approach not only conserves raw materials but also reduces energy consumption and tool wear, contributing to a more sustainable production process.

From a cost perspective, the benefits of precision machining manifest through reduced failure rates, lower returns and warranty claims, and decreased downtime in downstream operations. Products that meet specifications the first time require fewer adjustments and inspections, leading to smoother production cycles and faster delivery timelines. This reliability in manufacturing contributes to stronger brand reputation and customer satisfaction.

Additionally, as manufacturers adopt more environmentally conscious practices, precision machining aligns well with goals for minimizing scrap and optimizing resource usage. Innovations such as dry machining, coolant recycling, and additive-subtractive hybrid systems further enhance the sustainability profile of precision machining operations.

In a world increasingly focused on lifecycle cost and environmental impact, the advantages of precision machining go beyond technical superiority. They create a foundation for responsible manufacturing that balances performance, quality, and ecological stewardship.

Conclusion

Precision machining stands as a critical enabler of high-quality, high-performance products across virtually every major industry. Its ability to deliver components with microscopic accuracy and exceptional consistency directly impacts product functionality, safety, and market readiness. The benefits of precision machining extend beyond the shop floor—supporting innovation, improving sustainability, and reducing long-term costs.

By embracing high tolerance machining, manufacturers not only meet the rising demands of modern consumers but also future-proof their operations in an increasingly competitive and quality-driven global market. Whether crafting aerospace components or biomedical devices, precision machining remains the gold standard for excellence in manufacturing.

Need Steel Fabricators in Hermiston, OR?

NW Metal Fabricators, Inc. is a family-owned business that has been servicing customers in Hermiston, Oregon since 1986. We have more than 100 years of experience in the food-processing industry and specialize in the custom production of storage bins, conveyors, catwalks, handrails, gates, storage tanks, water heater tanks, sanitary piping, steam piping, and trailer truck hitches. NW Metal Fabricators, Inc. is an accredited member of the local Chamber of Commerce. We are a dedicated business where quality always comes first. Our customers know that they can count on us to make sure that their products are hand-crafted to meet their specifications. Contact us today to learn more about what we can do for you!

Categorised in: Machining

This post was written by admin