Does My Project Need Laser Cutting, Plasma Cutting, or Waterjet?

July 10, 2025 3:53 pm Leave your thoughtsWhen it comes to choosing the best metal cutting method for your project, the debate of laser vs plasma vs waterjet is unavoidable. Each of these technologies has made a significant mark in the manufacturing industry, offering precision and versatility in different contexts. Whether you are building high-precision components, working with thick industrial plates, or creating intricate designs in delicate materials, the right choice depends on several key factors. Let’s dive into a comprehensive metal cutting methods comparison so you can make an informed, confident decision for your next project.

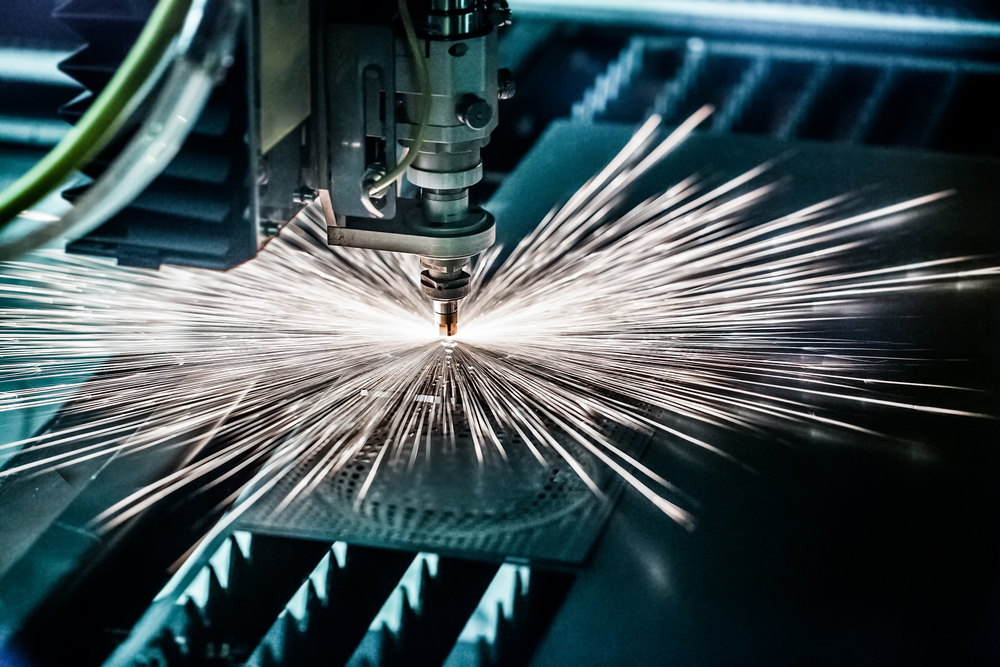

Laser Cutting

Laser cutting is a high-precision, non-contact cutting method that relies on a focused beam of light to melt, burn, or vaporize material. It is renowned for its extraordinary accuracy, with the ability to achieve extremely fine tolerances and minimal kerf width. Laser cutting excels at cutting thin to medium-thickness materials, typically up to about 1 inch for steel, and even higher for non-ferrous metals or plastics depending on the power of the laser. It’s particularly suited for applications that demand high repeatability and sharp, clean edges with minimal finishing work.

One of the key strengths of laser cutting is its speed on thin materials. Because the beam is so concentrated, it can move rapidly through sheet metal while producing crisp, detailed cuts. This makes laser cutting highly attractive for industries such as aerospace, electronics, medical devices, and automotive, where precision and tight tolerances are critical. In addition, modern laser cutters can integrate CNC systems to automate complex design patterns with remarkable consistency.

However, laser cutting does come with limitations. As material thickness increases, laser cutting can struggle to maintain edge quality, with possible tapering or heat-affected zones. Highly reflective metals, such as copper or brass, may also pose challenges, requiring specialized equipment or adjustments to avoid laser beam reflection that can damage the machinery. And while laser cutters are versatile, their capital cost can be relatively high, especially for industrial-grade systems. Still, if your project prioritizes tight tolerances and high production speed on thin to moderate materials, laser cutting is a compelling option.

Plasma Cutting

Plasma cutting takes a different approach by using a high-velocity jet of ionized gas, or plasma, to melt and sever conductive materials. The plasma arc reaches temperatures well beyond 20,000°C, instantly vaporizing metal and blowing it away with a strong gas flow. Plasma cutting has become a staple in the fabrication world, appreciated for its robustness, affordability, and ability to cut thicker metals with relative ease.

In terms of thickness, plasma cutting has a significant advantage over laser cutting. It can handle mild steel up to 2 inches thick or more, depending on the system’s amperage. It is also quite fast on medium to thick materials, making it highly cost-effective for industrial applications like shipbuilding, heavy equipment, structural steel fabrication, and metal recycling. If you’re dealing with structural steel or other heavy-gauge materials, plasma can quickly deliver the results you need.

However, there are trade-offs. Plasma cutting generally has a wider kerf and less precise tolerances compared to laser cutting, which means more secondary finishing work may be required. The heat-affected zone is also larger, which can cause slight warping on thin or delicate materials. While plasma cutters are portable and flexible, they are limited to conductive materials and cannot be used on glass, wood, or ceramics.

When balancing cost, speed, and thickness capabilities, plasma cutting is an outstanding middle-ground solution. For many metalworking shops, the plasma cutter offers a combination of affordability, ruggedness, and efficiency that is hard to beat, especially in environments where high volume or heavy-duty projects dominate.

Waterjet Cutting

Waterjet cutting is another versatile method, using an ultra-high-pressure jet of water, often mixed with an abrasive, to erode and cut through materials. The standout advantage of waterjet cutting is its ability to process virtually any material: metals, composites, stone, glass, ceramics, and even rubber or foam. This universal capability makes it a favorite in industries with diverse material requirements, such as architecture, aerospace, and artistic fabrication.

Unlike laser and plasma cutting, waterjet cutting is a cold-cutting process. This means there is no heat-affected zone at all, preserving the mechanical properties of the material and eliminating concerns about warping or micro-cracking due to thermal stress. This makes waterjets perfect for materials prone to heat distortion or sensitive composites that might degrade under high temperatures.

Waterjets can handle extremely thick materials as well, up to 12 inches or more depending on the pump pressure and abrasive type. They also offer exceptional precision, with tolerances comparable to laser cutting, though typically at a slower cutting speed. The versatility comes at a price, though: waterjet systems tend to have higher operating costs, including abrasive media, water recycling, and maintenance. They also generally cut more slowly than plasma or laser cutters, making them less efficient for high-volume, high-speed production runs.

For projects involving diverse, heat-sensitive, or very thick materials — or where a polished, ready-to-finish edge is crucial — waterjet cutting is a solid contender. Its versatility and cold-cutting advantages are unmatched by plasma or laser systems, even if they require more time and higher operating budgets.

How to Choose for Your Project

The laser vs plasma vs waterjet debate ultimately boils down to understanding your project’s priorities. First, consider material type. If you’re only cutting conductive metals, plasma might be your best value option, especially for thicker gauges. If you need to cut a wide range of materials, including non-conductive ones, waterjet is the clear winner.

Next, think about thickness. Thin to moderately thick materials (under about 1 inch) are ideal for laser cutting, thanks to its speed and superior finish. For thicker steel in the 1–2 inch range, plasma is typically more cost-effective and faster. If you’re going beyond several inches in thickness or need absolutely no thermal distortion, waterjet becomes the strongest choice.

Precision is another key dimension. Laser cutting offers the tightest tolerances for metals with the least secondary processing, closely followed by waterjet, while plasma is best for applications where fine tolerances are less critical. Budget also plays a vital role: plasma cutters have a much lower upfront cost and maintenance bill than high-power industrial laser or waterjet systems.

Finally, think about the production environment. If you have high-volume needs with repeatable parts, laser cutting’s speed and automation can dramatically boost productivity. In a shop with frequent material changes and one-off parts, the flexibility of a waterjet may be worth the investment. And for rugged, thick, conductive metals with minimal fuss, plasma is the reliable workhorse.

Putting It All Together

As you weigh the pros and cons in this metal cutting methods comparison, remember that no single method is universally superior. Instead, it’s about matching the tool to the unique demands of your project. Laser cutting is the go-to for speed and fine detail on thin materials, offering unmatched precision and clean edges. Plasma cutting thrives in heavy steel fabrication with its cost-effective, high-speed operation on thick, conductive metals. Meanwhile, waterjet shines with its cold-cutting capability and ability to handle virtually any material, preserving structural integrity with no heat-affected zone.

For many businesses, it’s worth exploring hybrid solutions or even outsourcing certain cuts to specialized shops with the right equipment, rather than investing heavily in all three technologies. Advances in CNC controls and software mean each of these systems can be programmed to produce complex parts with repeatable quality, making them all viable depending on the circumstances.

Ultimately, by understanding your material types, thicknesses, precision needs, production volume, and budget, you can confidently choose the right method. Whether you’re prototyping precision aerospace brackets, cutting structural beams for a skyscraper, or creating ornate stone signage, knowing the strengths of laser, plasma, and waterjet cutting will empower you to select the ideal technology for flawless results.

This holistic, thoughtful approach ensures your next project will benefit from the most efficient, cost-effective, and high-quality cutting process available — a smart investment for your team and your bottom line.

Need Steel Fabricators in Hermiston, OR?

NW Metal Fabricators, Inc. is a family-owned business that has been servicing customers in Hermiston, Oregon since 1986. We have more than 100 years of experience in the food-processing industry and specialize in the custom production of storage bins, conveyors, catwalks, handrails, gates, storage tanks, water heater tanks, sanitary piping, steam piping, and trailer truck hitches. NW Metal Fabricators, Inc. is an accredited member of the local Chamber of Commerce. We are a dedicated business where quality always comes first. Our customers know that they can count on us to make sure that their products are hand-crafted to meet their specifications. Contact us today to learn more about what we can do for you!

Categorised in: Metal Cutting

This post was written by admin