What’s the Difference Between Machining and Fabrication?

May 10, 2025 1:21 pm Leave your thoughtsWhen it comes to manufacturing, two common terms that often come up are “machining” and “fabrication.” While both are essential processes in shaping raw materials into usable products, they represent distinct techniques with different methods and applications. Understanding the difference between machining and fabrication is crucial for anyone involved in the production process, whether you’re a manufacturer, engineer, or even a hobbyist working on a project. In this blog post, we will explore the nuances of machining and fabrication, highlighting their differences, advantages, and how they are applied in various industries.

Defining Machining

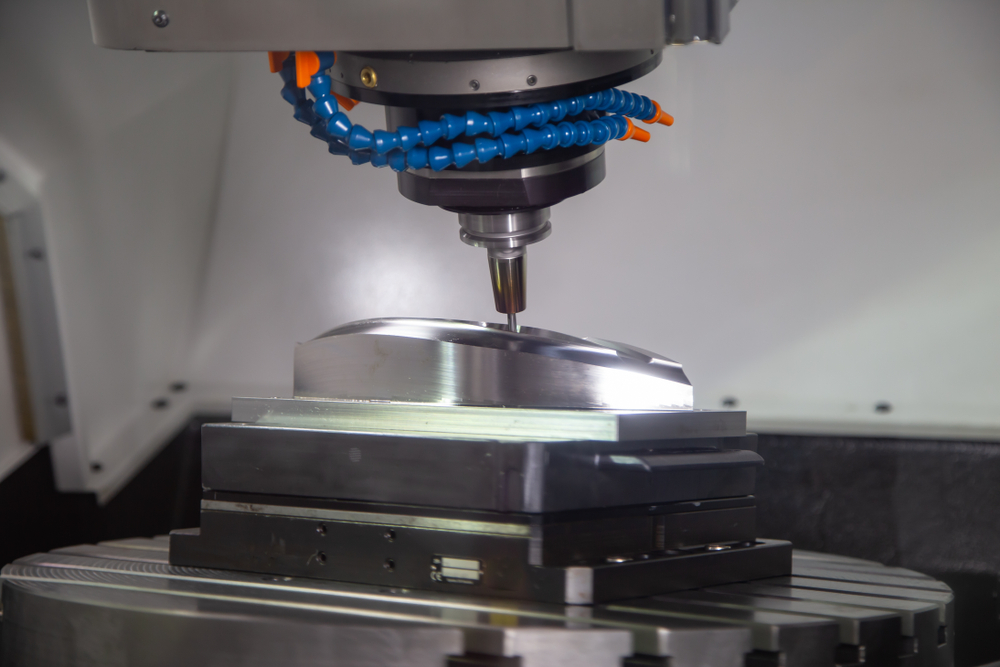

Machining is a manufacturing process that involves the removal of material from a workpiece to achieve a desired shape or finish. This process typically uses tools like lathes, mills, drills, or grinders to shape and refine the material. The primary goal of machining is to produce precise, highly detailed parts, often with tight tolerances and smooth surfaces. Machining is most commonly used with metals, but it can also be applied to other materials such as plastics and composites.

One of the key features of machining is that it begins with a solid block of material, and the machine tools remove portions of that material until the final shape is achieved. For instance, in turning operations, a rotating workpiece is cut by a stationary tool, removing material layer by layer until the desired diameter or profile is reached. Similarly, milling involves a rotating cutting tool that removes material from the workpiece as it moves in multiple directions, allowing for complex shapes to be formed.

Machining is an essential process in industries where precision and accuracy are paramount, such as aerospace, automotive, and medical device manufacturing. Parts like engine components, gears, and intricate tools often undergo machining due to the need for high tolerances and fine details.

Understanding Fabrication

Fabrication, on the other hand, is a broader term that encompasses a variety of processes used to create metal structures and products. Unlike machining, which involves removing material from a solid block, fabrication typically involves building up or assembling components. The processes involved in fabrication include cutting, bending, welding, assembling, and sometimes finishing. Fabrication often deals with larger structures or items that require assembly from individual parts.

For example, in metal fabrication, a large sheet of steel might be cut into various shapes and sizes, then welded together to form a frame for a building, machinery, or other infrastructure. This process might also involve bending metal pieces into specific shapes or assembling pre-fabricated parts using fasteners or welding. Fabrication is crucial in industries like construction, shipbuilding, and infrastructure development, where large-scale components and structures need to be created.

The difference in approach between machining and fabrication is significant. Fabrication is more about transforming raw materials into a finished product by joining, cutting, or shaping them, often without the extreme precision required in machining. Fabricators might use tools like plasma cutters, lasers, or press brakes to perform their tasks, and the resulting product may not require the fine finishing and tolerances that machining offers.

The Key Differences Between Machining and Fabrication

While both machining and fabrication are vital to manufacturing, the processes differ significantly in terms of their approach, equipment used, and applications. One of the most important distinctions lies in the method of material manipulation. Machining involves removing material from a solid block to create the desired part, while fabrication typically builds up a structure by assembling pre-cut or pre-formed components.

Another key difference is the level of precision. Machining processes, due to the nature of their tools and techniques, can achieve much higher precision than fabrication processes. Machining is ideal for producing parts that require fine details, tight tolerances, and smooth finishes, such as precision components for machinery or medical devices. Fabrication, while it can also be highly accurate, generally focuses more on creating larger structures, such as frames, enclosures, or even entire buildings, where the tolerance for small imperfections is higher.

The types of materials used in each process also differ. Machining is most commonly used with hard metals, such as steel, aluminum, or titanium, but can also be applied to softer materials like plastics. Fabrication, on the other hand, can involve a broader range of materials, including metals, plastics, and even wood, depending on the application. In fabrication, materials are often more versatile and can be manipulated in various ways, such as welding them together, bending them, or assembling them into larger structures.

Finally, the overall cost and time requirements can differ between the two methods. Machining is often a more time-consuming and expensive process because of the high level of precision and the specialized equipment required. In contrast, fabrication processes can be faster and more cost-effective, especially when dealing with larger volumes of parts or simpler structures. However, the complexity of the design and the materials used can also impact the cost and time required for fabrication.

Applications of Machining

Machining is primarily used for producing parts that require high precision and fine details. Some of the most common applications of machining can be found in industries such as aerospace, automotive, and medical device manufacturing. For instance, in the aerospace industry, machining is crucial for creating components like turbine blades, which need to be fabricated to extremely tight tolerances to ensure they function correctly in high-performance environments.

In automotive manufacturing, machining is often used to create engine components, gears, and other critical parts that must operate smoothly and efficiently. Similarly, medical devices, such as surgical instruments or implants, require machining to ensure they meet strict regulatory standards and perform with the necessary accuracy.

Another application of machining is in the production of complex tooling or molds used for other manufacturing processes. For example, machining might be used to create molds for injection molding or die-casting, where the mold must have highly detailed surfaces to produce high-quality parts.

Machining is also indispensable in industries where custom or one-off parts are required. For example, a manufacturer producing low volumes of a specific part may rely on machining to create precise prototypes or limited-edition products.

When Fabrication is the Preferred Choice

While machining is vital for many industries, there are plenty of applications where fabrication is the better choice. Fabrication is particularly well-suited for creating large, complex structures or assemblies where high precision is not the primary concern. Industries such as construction, shipbuilding, and infrastructure development rely heavily on fabrication processes to build everything from bridges to large machinery and heavy-duty equipment.

Fabrication also plays a crucial role in the creation of products with large surface areas or those that need to be assembled from multiple components. For example, in the construction of buildings or bridges, metal fabrication is used to create beams, frames, and other structural elements that will later be welded, bolted, or fastened together. Similarly, in the automotive industry, fabrication is often used to create large body panels or structural components before they are welded or bolted into place on the vehicle’s frame.

Additionally, fabrication is the go-to process for creating prototypes or small batches of products that don’t require the precision that machining offers. Since fabrication can involve processes like welding and cutting, it can often be faster and more cost-effective when working with large parts or assemblies.

Conclusion

Machining and fabrication are both essential processes in the manufacturing world, each serving different needs and applications. Machining focuses on removing material from a solid block to create precise, detailed parts with tight tolerances, making it ideal for industries that require high accuracy and smooth finishes. Fabrication, on the other hand, involves the assembly of parts and the shaping of materials to form larger structures, making it the preferred method for building large-scale products and assemblies.

Understanding the difference between machining and fabrication can help manufacturers, engineers, and even hobbyists make the right choice for their projects. Whether precision is the priority or large-scale assembly is needed, both machining and fabrication offer unique advantages that cater to specific manufacturing needs.

Need Steel Fabricators in Hermiston, OR?

NW Metal Fabricators, Inc. is a family-owned business that has been servicing customers in Hermiston, Oregon since 1986. We have more than 100 years of experience in the food-processing industry and specialize in the custom production of storage bins, conveyors, catwalks, handrails, gates, storage tanks, water heater tanks, sanitary piping, steam piping, and trailer truck hitches. NW Metal Fabricators, Inc. is an accredited member of the local Chamber of Commerce. We are a dedicated business where quality always comes first. Our customers know that they can count on us to make sure that their products are hand-crafted to meet their specifications. Contact us today to learn more about what we can do for you!

Categorised in: Machining, Metal Fabrication

This post was written by admin