Cost-Effective Tips for Small-Scale Metal Fabrication

May 28, 2024 4:22 pm Leave your thoughtsMetal fabrication is a vital process in various industries, from manufacturing and construction to automotive and aerospace. While large-scale metal fabrication operations may have access to extensive resources and equipment, small-scale fabricators often face challenges in achieving cost-effectiveness and efficiency. However, with strategic planning, smart decision-making, and the right techniques, small-scale metal fabrication businesses can optimize their operations and minimize costs. In this guide, we’ll explore cost-effective tips for small-scale metal fabrication, providing practical advice to help businesses maximize efficiency and savings in their operations.

Understanding Small-Scale Metal Fabrication

What is Small-Scale Metal Fabrication?

Small-scale metal fabrication refers to the process of cutting, shaping, and assembling metal components or structures on a smaller, more localized scale. It often involves smaller production runs, limited resources, and a focus on custom or niche products tailored to specific customer requirements.

Challenges in Small-Scale Fabrication

Small-scale metal fabrication businesses face several challenges, including:

- Limited Resources: Smaller budgets and fewer resources may restrict access to advanced machinery, equipment, and materials.

- Efficiency: Maximizing efficiency and productivity while minimizing waste and downtime is crucial for small-scale operations to remain competitive.

- Cost Control: Managing costs and overhead expenses is essential for profitability and sustainability in the long term.

Cost-Effective Tips in Metal Fabrication

Prioritize Planning and Design

Effective planning and design are fundamental to cost-effective metal fabrication. Invest time and effort into detailed planning and design to minimize material waste, optimize production processes, and ensure accurate and efficient fabrication.

Optimize Material Usage

Maximize material efficiency by optimizing nesting layouts, utilizing offcuts or remnants, and minimizing scrap generation. Consider alternative material options, such as recycled or reclaimed metals, to reduce costs and environmental impact.

Embrace Lean Manufacturing Principles

Implement lean manufacturing principles to streamline processes, eliminate waste, and improve productivity. Identify and eliminate bottlenecks, optimize workflow layouts, and standardize operating procedures to maximize efficiency and reduce costs.

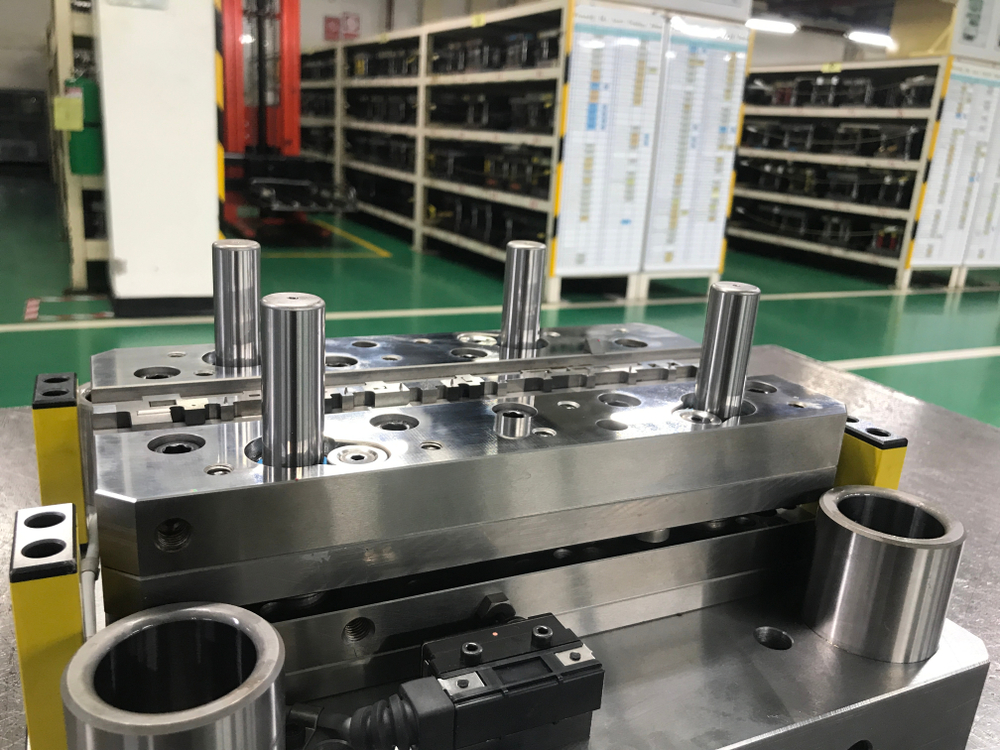

Small Scale Metal Fabrication

Invest in Versatile Equipment

Invest in versatile equipment and machinery that can perform multiple functions or accommodate a variety of fabrication tasks. Look for modular or adaptable equipment solutions that offer flexibility and scalability for small-scale operations.

Embrace Technology and Automation

Embrace technology and automation to increase productivity and reduce labor costs. Explore software solutions for design, CAD/CAM programming, and CNC machining to streamline production processes and improve accuracy.

Leverage Outsourcing and Partnerships

Consider outsourcing certain fabrication processes or partnering with specialized suppliers or manufacturers to reduce costs and expand capabilities. Outsourcing non-core tasks or components can free up resources and focus on core competencies.

Conclusion

Cost-effective metal fabrication is essential for small-scale businesses to remain competitive and profitable in today’s market. By prioritizing planning and design, optimizing material usage, embracing lean manufacturing principles, and leveraging technology and automation, small-scale metal fabricators can maximize efficiency, minimize costs, and achieve sustainable growth. Whether you’re a startup or established business, implementing these cost-effective tips in metal fabrication can help you optimize your operations and achieve success in the competitive metal fabrication industry.

Need Steel Fabricators in Hermiston, OR?

NW Metal Fabricators, Inc. is a family-owned business that has been servicing customers in Hermiston, Oregon since 1986. We have more than 100 years of experience in the food-processing industry and specialize in the custom production of storage bins, conveyors, catwalks, handrails, gates, storage tanks, water heater tanks, sanitary piping, steam piping, and trailer truck hitches. NW Metal Fabricators, Inc. is an accredited member of the local Chamber of Commerce. We are a dedicated business where quality always comes first. Our customers know that they can count on us to make sure that their products are hand-crafted to meet their specifications. Contact us today to learn more about what we can do for you!

Categorised in: Metal Fabrication

This post was written by admin